Blog

Share this

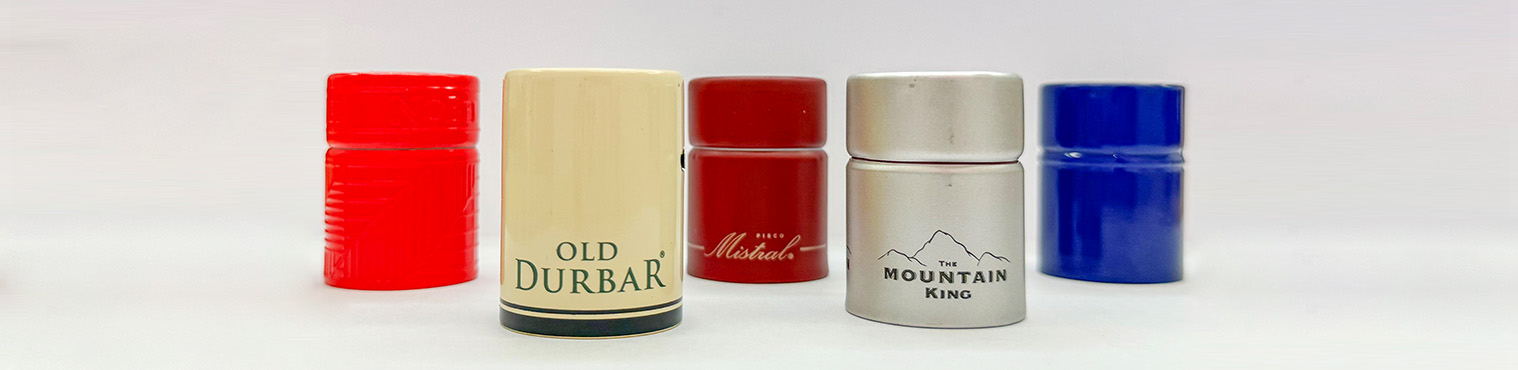

What Are Main Types of Metal Soda Bottle Caps

Jul 14, 2025 17:46:57

In the world of soda water, the bottle cap is small but plays a vital role. It not only ensures the retention of bubbles in the bottle and maintains the taste of soda water, but also ensures the safety of the product during storage and transportation.

Commonly used metal materials

Aluminum

Aluminum bottle cap is one of the main metal soda bottle caps. It has the characteristics of light weight, which reduces the overall weight of the packaging and makes it more convenient for consumers to carry it during transportation.

At the same time, aluminum has good corrosion resistance, can effectively prevent rust, and ensure that the bottle cap can maintain good performance in various environments. Alloys such as 8011 - H14, 1060, 1235, 3004, and 3105 have good deep drawing performance, low earing rate, and excellent sealing, plasticity, and corrosion resistance, which can well meet the needs of soda water packaging.

In addition, aluminum also has good processing performance and can be finely processed on a production line with a high degree of automation to produce bottle caps with simple appearance and exquisite patterns.

Moreover, aluminum can be recycled, which conforms to the current concept of environmental protection. Compared with plastic bottle caps, it also has certain advantages in performance and cost.

Tinplate and chromeplate

Tinplate and chromeplate are also common materials for making bottle caps. Tinplate has good weldability and corrosion resistance, while chromeplate has good decorativeness and corrosion resistance. Initially, bottle caps were mostly made of aluminum, but nowadays they are commonly made of tinplate and chromeplate, lined with polyvinyl chloride plastic pads, and are mostly used for packaging beer, soft drinks (including soda water), and seasonings.

This combination of materials can provide reliable sealing performance, protecting the soda water in the bottle from external factors, and at the same time, its surface can be coated with outer wall and printed with trademarks to enhance the recognition and aesthetics of the product.

Application Scenarios

Soda canning

In the field of soda canning, metal bottle caps are widely used. The soda can bottle top is made of materials that comply with international regulations for food contact materials and provide extreme durability and integrity, preserving the freshness and flavor of the soda in the can. Whether on supermarket shelves or in vending machines, most of the canned sodas we commonly see use metal bottle lids, which are popular with consumers for their convenient opening method and good sealing performance.

Glass Bottle Packaging

For soda in glass bottles, metal screw caps are a common choice. Metal screw caps are generally made of aluminum or tin-coated sheet with a PVC pad lined inside. This design is suitable for solid beverages packaged in wide-mouth bottles, and is also suitable for soda in glass bottles.

In the market, some high-end or specialty glass-bottled soda water we see often uses carefully designed metal bottle caps, which not only play a sealing role, but also enhance the overall texture and brand image of the product.

Original source: https://www.alubottlecaps.com/a/what-are-main-types-of-metal-soda-bottle-caps.html

Previous : What Are Thread Plastic Caps Used For

Share this

- Email: sale@alubottlecaps.com

- Tel: +86-15978414719

- Address: CBD, Zhengzhou, Henan, China

Inquiry

We will reply to you as soon as possible