Blog

Share this

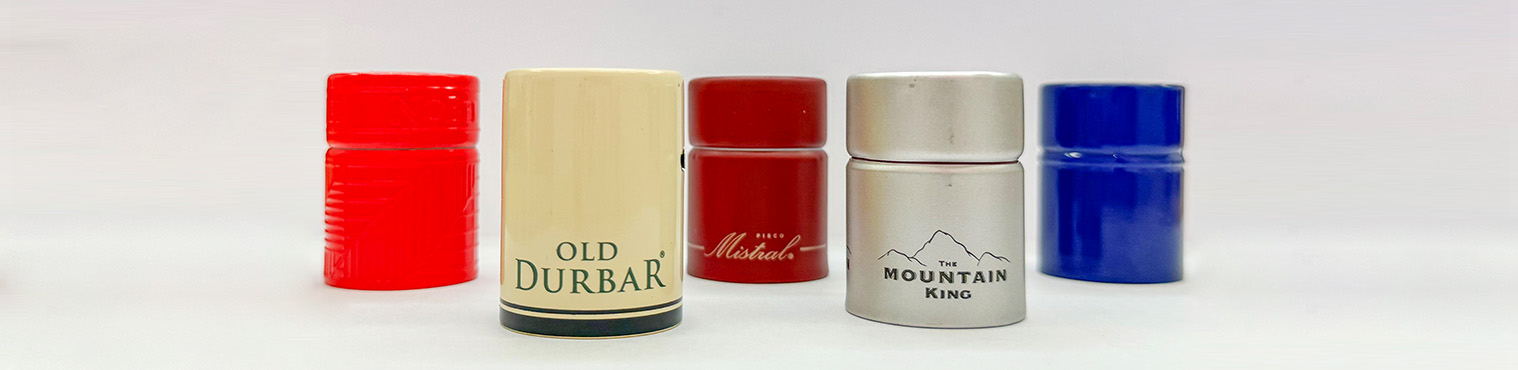

Different Types of Red Wine Bottle Caps

Apr 17, 2025 11:37:39

In the field of wine packaging, aluminum bottle caps are subverting tradition with their excellent sealing and convenience. From Australia to New Zealand, from daily table wine to high-end wine, the market penetration rate of aluminum bottle caps has exceeded 35%. Among them, Screw Cap and Twist Cap, as two mainstream designs, although they belong to the aluminum bottle cap family, show significant differences in structure, function and application scenarios.

Aluminum screw cap

The screw cap consists of an aluminum shell and an internal sealing liner. The shell surface is rolled out with precision threads, which perfectly match the thread groove of the bottleneck and achieve an airtight seal by rotation. The liner material is mostly polyethylene (PE) or polyvinylidene chloride (PVDC), which has low air permeability and corrosion resistance, and can prevent wine oxidation.

Screw caps on wine bottles with an elastic liner can maintain a stable seal in a temperature range of -5℃ to 40℃. Some high-end screw caps also integrate Oxygen Transfer Rate (OTR) control technology, which can accurately control the amount of oxygen entering the bottle by adjusting the thickness of the liner to meet short-term aging needs.

Aluminum twist cap

Twist caps are usually made of metal or plastic, with a resin pad inside, and are fixed to the bottle mouth through a snap-on structure. There is no thread on the top, but the four-point inward bend protrusion of the cap edge is buckled into the thread groove of the bottleneck to form a mechanical lock.

Due to the lack of thread guide, the sealing of the twist cap depends on the size accuracy of the bottle mouth and the assembly pressure, and there may be a risk of leakage caused by the error of the bottle mouth.

Differences

Dimensions | Aluminum Screw cap | Aluminum Twist cap |

Sealing mechanism | Thread + gasket double seal, excellent airtightness, can isolate 99.9% of oxygen | Buckle + resin pad, relying on physical buckle, the sealing is slightly inferior to the screw cap. |

Opening method | It needs to be rotated 3-5 times, and the opening force is uniform, which is suitable for arthritis patients or female users. | It can be opened by twisting 1/4 turn directly, similar to the beverage bottle cap, and it is more convenient to operate with one hand. |

Cost structure | The cost of a single bottle is about 5-6 cents, and the advantages of large-scale production are obvious. | The cost of metal twist caps is slightly higher (about 8-10 cents). |

Environmental performance | 100% recyclable | 100% recyclable |

Market Positioning | Dominates the mid-to-high-end market. | Mainly focuses on economical wines |

Applications

Uses of aluminum screw cap

1. White wine and red wine:

The high sealing performance of screw caps perfectly preserves the fruit aroma. For example, the red wine in New Zealand uses screw caps, which can maintain the citrus and herbal aroma for more than 5 years.

2. Sustainable certified wines:

Screw caps made of recycled aluminum meet EU green packaging standards, such as the organic series of Australian brand Yellow Tail.

Uses of aluminum twist cap

Some sparkling wines use metal twist caps (such as Italian Prosecco), but they need to be equipped with leak-proof liners to prevent carbon dioxide leakage.

The convenience of red wine with twist top makes them the first choice for music festivals, picnics and restaurants, such as the tap design of Franzia boxed wine in the United States.

Original source: https://www.alubottlecaps.com/a/different-types-of-red-wine-bottle-caps.html

Share this

- Email: sale@alubottlecaps.com

- Tel: +86-15978414719

- Address: CBD, Zhengzhou, Henan, China

Inquiry

We will reply to you as soon as possible